Acoustic Feedback Improves Automated Feeding Systems for Shrimp

| Wed, 06 May 2020 - 10:28

Shrimp feeds are the most important variable cost, source of nutrients and biological waste in semi-intensive and intensive systems. Albeit currently available feeds are generally considered adequate, there are several studies focusing on optimizing shrimp nutrition through either feed formulation or feeding protocols. As with other species, there are multiple studies and commercial reports validating production viability with less-costly, more sustainable soy-based feeds. However, feed management is the conjugation of nutritional content and feed delivery mechanism. While much research focused on nutrition and feed formulation, little effort is put into feed delivery practices. Hence, our group focuses on improving feed management techniques through systematic evaluations of different techniques.

To optimize feed delivery methods, it is essential to understand shrimps’ natural feeding behavior. Shrimp are benthic grazers with limited capacity to store ingested feed which results in preferring frequent ingestion of small quantities of food. Multiple authors have reported better growth when shrimp meals were increased which also allows higher feed inputs since nutrient loading is spread over a longer time period. Reis et.al (2019) reported that when using automated feeding systems higher growth rate occurred with increasing levels of feed input.

Testing soy-optimized feeds and automated feeding systems in shrimp pond production

Presently, many shrimp farms around the globe still rely on human labor to feed shrimp, therefore increasing the number of meals often results in higher labor costs. Moreover, penaeid shrimp naturally feed at night, which could logistically complicate management even more. This issue is particularly important in central America where wages are higher than in other shrimp production regions such as Southeast Asia.

Utilization of automatic feeders is a solution to increase number of meals without compromising labor costs. Timer feeders have been used by the shrimp industry for well over a decade but more recently acoustic feedback feeding technology was developed and made commercially available. This is a type of on-demand feeding system that integrates live acoustic recording shrimp activity as the factor to determine when to feed. Ulman et al. (2019) and Reis et al. (2019) have reported faster growth and higher product value for semi-intensive system utilizing acoustic feedback feeding systems.

Even though by definition a timer-feeder will never be as efficient as a demand feeder, results by Reis et al. (2019) indicate that it is possible to reduce the efficiency gap between timer-feeders and demand acoustic feedback feeding systems. Although published data on automatic feeder utilization is available, there is little to no information about preferred feeding schedule in outdoor pond production environment.

The goal of our work has been to systematically explore the potential for integration of automatic feed delivery systems in shrimp aquaculture, particularly in outdoor pond systems. This specific project described here had the objective of finally establishing a standard feeding protocol for timer feeders in shrimp production through the evaluation of shrimp growth fed different feed amounts through different schedules. In short, assessing if approximation to natural feeding behavior schedule (nighttime) would favor growth.

As reported for previous years, it has been carried out in parallel with a commercial acoustic demand-feeding system (AQ1 Systems, Tasmania, Australia), which has allowed the validation of this technology under a practical production scenario. In addition to a practical feed demonstration using new automated technology, these data demonstrate the efficacy and performance of shrimp on soy-optimized feeds.

Study design

This study was performed at the Alabama Department of Conservation and Natural Resources, Claude Peteet Mariculture Center, Gulf Shores, Alabama (USA). Pacific white shrimp (Litopenaeus vannamei) larvae were obtained from American Penaeid (Fort Myers, Fla., USA), acclimated and nursed in a greenhouse system. Juvenile shrimp were then stocked into 16 outdoor, 0.1-hectare (ha) ponds at 35 shrimp per square meter.

Feed management

All ponds were offered the same two diets: a 1.5-mm commercial diet (40 percent crude protein, 9 percent crude lipids) produced by Zeigler Bros. Inc. (ZBI, Gardners, Pa., USA) for the first four weeks, and a 2.4-mm ZBI diet with 35 percent protein, 8 percent lipid diet and fed from the fourth week on. Four treatments were set to evaluate shrimp growth performance under different feeding protocols. Feed inputs for all treatments were calculated based on a standard feeding protocol (SFP) that expects weight gain of 1.3 grams per week, a feed conversion ratio (FCR) of 1.2, and expected population based on a 1.5 percent weekly mortality during the grow-out period. All treatments were fed the same amount twice a day during the first 30 days of production and only then started the differential feed management throughout the cycle.

Three timer-feeder treatments using commercial units (BioFeeder, S.A., Guayaquil, Ecuador) were used to distribute 34 meals evenly spread throughout the following schedules: Daytime (0700 to 1900), Nighttime (1900 to 0700) and 24 hours. Based on previous data, we developed a standard feeding protocol for automatic feeding systems (SPAF) for all timer-feeder treatments where feed inputs were adjusted to SFP+30 percent during the first 45 days of production, SFP+45 percent from day 46 through 60, and SFP+60 percent from day 60 through 90. The 24-hour treatment feed inputs were further increased to SFP+75 percent from day 75 through 90.

A fourth treatment was also used in this experiment, which consisted of the AQ1 Systems technology. This is an on-demand acoustic feedback feeding system that integrates shrimp acoustic input through a hydrophone inside the pond and feeds accordingly. This system was initiated 30 days into the production cycle and was also set to feed ad libitum until a maximum of 16 kg per day in order to avoid water-quality degradation to critical levels. This system was also equipped with a dissolved oxygen (DO) sensor in order to further self-regulate both feeding and mechanical aeration. Each treatment was replicated in four ponds.

Sampling and water quality

Shrimp were sampled weekly through the entire production stage using a cast net (1.52 meters radius; 0.96 cm mesh) to collect approximately 60 individuals per pond. Pond sampling enabled growth assessment and inspection for general health. Ponds were monitored (DO, temperature, salinity and pH) at least three times a day, at sunrise (5:00 to 5:30 a.m.), afternoon (2:00 to 2:30 p.m.) and sunset (7 to 8 p.m.). For maintenance of dissolved oxygen (DO) above 3 mg/L, all ponds were supplied with one 2-HP Aire-O2 (Aire-O2, Aeration Industries International, Inc., Minneapolis, Minn., USA) as a main source of mechanical aeration and one 1-HP Air-O-Lator (Kansas City, Mo., USA) for backup and/or supplemental aeration as needed.

Results and discussion

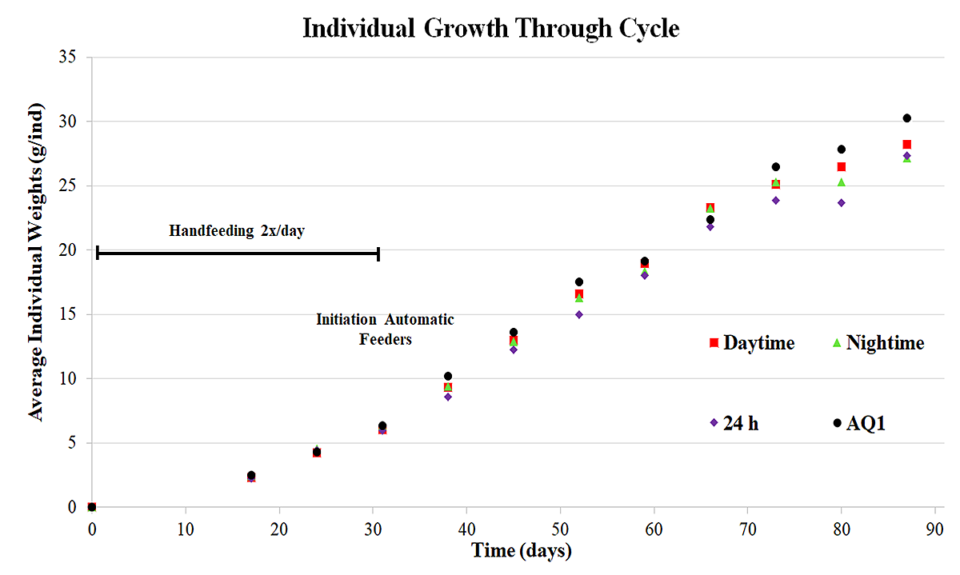

Growth rates (grams per week) for this trial are present in Fig. 2. These data validate results by various authors – including Napaupaiporn et al. (2013) . Ulman et al. (2019. and Reis et al. (2019) – that suggested better growth with utilization of the AQ1 Systems acoustic feedback system.

Fig. 1: Average individual weight per treatment throughout production cycle in this study.

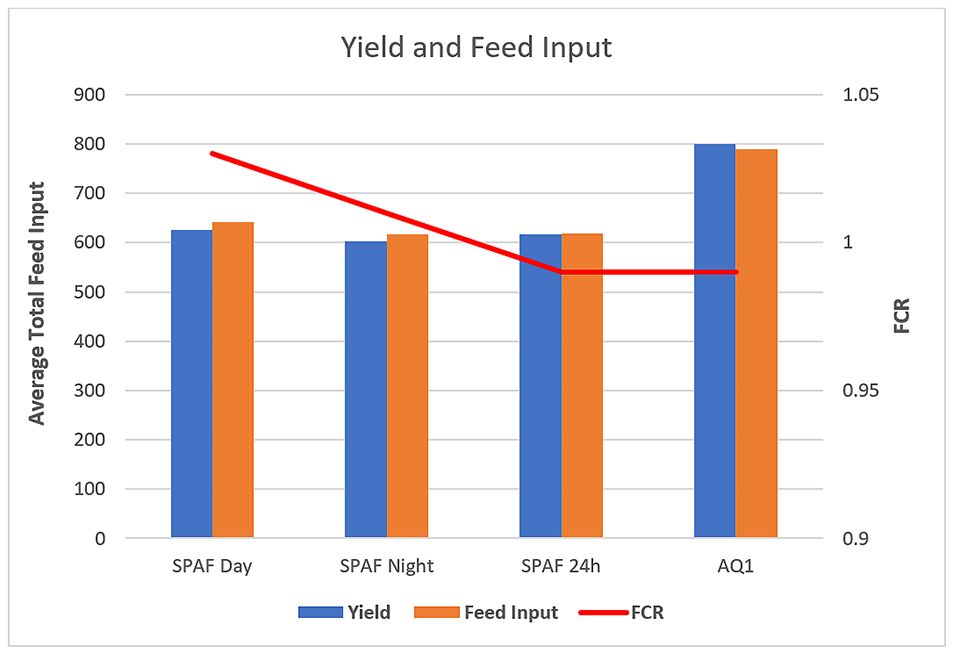

Also, in line with reported by previously mentioned authors, this project registered higher feed inputs in ponds using the AQ1 system (Fig. 2). Although no statistical differences were observed among feed inputs for automatic feeders, both nighttime and 24-hour feeding treatments fed numerically lower feed amounts than daytime treatment. As a natural consequence of differential feed inputs, this study has found differences between shrimp fed during nighttime and 24 hours and shrimp fed with AQ1 system for all individual final weight and weight gain (g/wk). Lower feed inputs were a consequence of skipping meals during nighttime as pond management practice to avoid oxygen depletion beyond our mechanical aeration capacity. This is likely an issue related to the setup of the ponds and its limited mechanical aeration capacity during nighttime, particularly in late growth stages. Therefore, differences are not expected in an identical setup where oxygen is not a limiting factor.

In short, the utilization of automatic feeders has allowed faster growth resulting in shorter production cycles, which ultimately results in higher shrimp yields. These results further validate the widely reported feed conversion ratios (FCRs) for automatic feeders across the board (Fig. 2).

Fig. 2: Yield and cumulative feed input for the different treatments in this study.

The main objective of this trial was to establish a new standard feeding protocol, specifically designed to automatic timer feeders. Based on the results for this trial and previously published data under identical experimental conditions (Ullman et al. 2019; Reis et al. 2019) and the results presented in this publication, it is clear that acoustic on-demand feeders are the most efficient and result in higher productivity. However, it is possible to establish high efficiency feeding protocols for timer-feeders. This is especially important for facilities that are equipped with timer feeders and would rather adjust feeding tables and protocols instead of reinvesting in higher technology acoustic on-demand feeders.

As reported by Iescovitch et al. and Ullman et al. (2019) and Reis et al. (2019), the conjunction of soy optimized diets and adequate feed management protocols in automatic feeding technologies resulted in good growth and productivity, including during this trial as well. The wide variety of production systems in shrimp aquaculture makes it virtually impossible to make broad conclusions regarding how long it would take for investment in automatic feeders to be recovered. However, it is clear that these technologies are an extremely useful tool to achieve higher productivity and a more valuable product.

Perspectives

The objective of this project was to update our standard feeding protocol into an optimized version for timer-feeders. Although the objective was successfully reached it remains clear that acoustic feedback systems have become the standard for optimal shrimp growth in pond culture. Therefore, future feed management work in our systems will likely focus on exploring the nutritional potential of different feeds while using the AQ1 system across all ponds.

Source: Global Aquaculture Alliance