The Future of Fish Farming may be Indoors

| Tue, 10 Sep 2019 - 09:05

New advancements in water filtration and circulation make it possible for indoor fish farms to dramatically grow in size and production

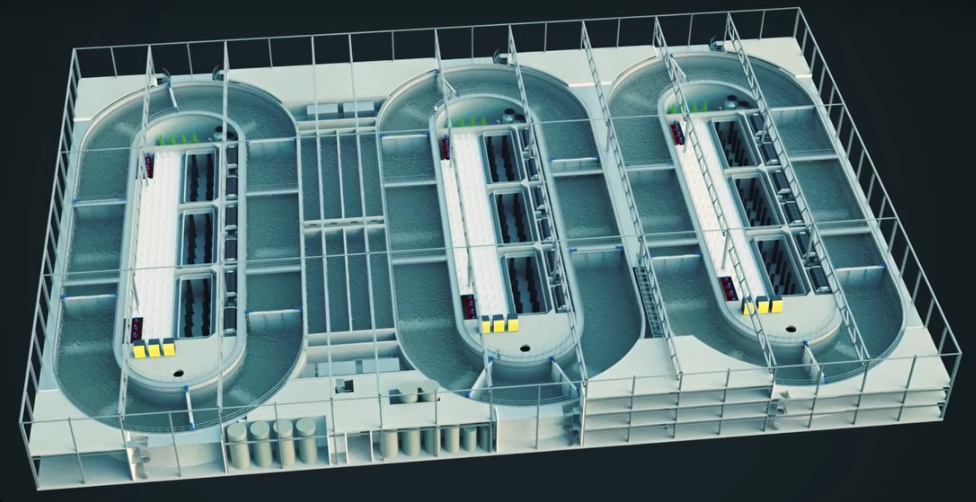

An artist’s rendition of salmon swimming through Nordic Aquafarm’s proposed tanks in Belfast, Maine. A constant current in the tanks will provide fish with exercise for optimal health and meat quality, the company says. Credit: Nordic Aquafarms

On a projection screen in front of a packed room in a coastal Maine town, computer-animated salmon swim energetically through a massive oval tank. A narrator’s voice soothingly points out water currents that promote fish exercise and ideal meat texture, along with vertical mesh screens that “optimize fish densities and tank volume.” The screens also make dead fish easy to remove, the narrator cheerily adds.

The video is part of a pitch made earlier this year for an ambitious $500-million salmon farm that Norway-based firm, Nordic Aquafarms, plans to build in Belfast, Maine, complete with what Nordic says will be among the world’s largest aquaculture tanks. It is one of a handful of projects in the works by companies hoping these highly mechanized systems will change the face fish farming—by moving it indoors.

If it catches on, indoor aquaculture could play a critical role in meeting the needs of a swelling human population, Nordic CEO Erik Heim says. He believes it could do so without the pollution and other potential threats to wild fish that can accompany traditional aquaculture—although the indoor approach does face environmental challenges of its own. “There’s always some risk, but the risk of the land-based system is a small percentage of the risk of an outdoor system,” says Michael Timmons, an environmental engineer at Cornell University who has studied aquaculture for more than 20 years and is not involved in the Nordic project.

Fish farming has often been touted as an extremely efficient way to produce animal protein: the Global Aquaculture Alliance claims 100 kilograms of fish feed can deliver up to 15 times more meat than an equivalent amount fed to cows. The industry has gained international traction, with farmed fish surpassing wild-caught ones (pdf) in the global food supply in 2014. But traditional fish-farming methods come with significant environmental drawbacks. For example, salmon farmers in Norway and Chile—the world leaders in salmon production—typically use open-ocean cages that corral fish in suspended netting or pens. This setup allows waste to flow directly into the environment, along with pathogens and parasites that can infect wild populations. Open-air pond farms—found worldwide and representing the most common type of aquaculture in China, the top global producer of farmed fish—also have a track record of polluting local waterways with fish effluent and veterinary medicines that are used to keep disease at bay.

Timmons contends land-based indoor systems can greatly reduce such risks. They isolate fish from the environment and remove most of the waste from the water using recirculating aquaculture systems (RAS), which are akin to filtration systems in a household fish aquarium, he says. But to date, indoor RAS farms have made up only a tiny fraction of the global market and are much smaller than Nordic’s planned operation. For example, Blue Ridge Aquaculture—the world’s largest RAS tilapia farm, located in Virginia—produces less than 10 percent of the quantity of fish Nordic expects to produce in Maine.

This recirculating technology has existed in some form since the 1970s, but has evolved enough in recent years that the Monterey Bay Aquarium’s Seafood Watch now ranks RAS-farmed fish as one of the most sustainable seafood choices available. So “the natural thing to do is to scale up,” Heim told Maine residents during his recent presentation. The Belfast operation would include 18 of what Heim says would be among the world’s largest aquaculture tanks—each three times the volume of an Olympic pool—and would ultimately produce 33,000 tons of fish, or roughly 8 percent of U.S. consumption, each year. The company plans to construct a similar farm in Norway next year that would contain tanks the same size, he says.

Although there are questions as to whether scaling up increases such a system’s environmental riskiness, some experts think the technology can make a sustainable transition to the big time. Community members in Heim’s audience voiced concerns about how wastewater might affect nearby coastal waters, but Timmons says the small amount of water discharged from RAS systems (from tank overflow and spray-cleaning waste from filters) is often cleaner than when it enters. Water in RAS tanks flows through a bubbling container called a bio-filter, in which bacteria consume fish urine and convert it into a form of nitrogen that is safe for the fish and environment, says Michael Schwarz, director of the Virginia Seafood Agricultural Research and Extension Center. Physical filters gather fish feces and leftover food that can be stored away and resold as compost or raw material for biogas. Ozone treatment helps break down frothy organic solids, and ultraviolet light is used to kill pathogens.

Salmon crowd together in a tank at the National Cold Water Marine Aquaculture Center in Franklin, Maine—a land-based aquaculture research facility that consults with companies like Nordic Aquafarms about best practices in salmon farming. Credit: Laura Poppick

This technology has already been tested and automated enough that scaling up can be as straightforward as “doubling the batter” for a batch of cookies, says Schwarz, who is not involved in the Belfast project. “There shouldn’t be any surprise if you design it properly and operate it properly,” he says. “If there is a surprise, someone didn’t do their job.”

This risk of human error should not be overlooked, says Brian Peterson, director of the National Cold Water Marine Aquaculture Center in Maine, where he uses recirculating systems to raise salmon for research purposes. Bio-security routines that require sanitizing hands and dipping shoes in disinfectant bins minimize the risk of disease and the need for antibiotics that other forms of aquaculture heavily rely on, says Peterson, who has advised Nordic Aquafarms regarding best practices. However, just one employee who fails to complete the process correctly or neglects other basic protocol could contaminate the operation—with pathogens potentially looping through the recirculating system and killing an entire tank of fish. Large-scale companies could guard against this with monitoring equipment that lets them respond quickly to any issues, Peterson says, adding that strict government permits require routine monitoring that would also detect unusual levels of discharge in wastewater.

The real environmental toll of big indoor systems will depend on the capacity of local infrastructure, including the water supply, Timmons says. Recirculating systems can recycle more than 90 percent of tank water but some of it does get lost to evaporation or absorbed in solid waste each day. He calculates that a farm the size of the Belfast facility would (after the initial tank fill) consume about 1.65 billion liters of freshwater per year—roughly equivalent to the water use of about 12,000 people. But he notes even in a town of fewer than 7,000 people, like Belfast, this is within the capacity of the local aquifer—and is dwarfed by the volume of water the farm would recycle each year. In more drought-prone regions indoor aquaculture facilities could release wastewater for irrigating agricultural fields, reducing the water burden, Timmons adds.

Pending state and federal permitting the Belfast facility will break ground in 2019, and Timmons believes it could pave the way for similar systems around the world. “If this facility is as successful as it appears it can be,” he says, “then that will certainly incentivize others to do similar types of farms.”

Source : Scientific America