New Floating Fish Farm Off Changi Aims to Produce More Seafood Than Traditional Coastal Farms

| Thu, 21 Nov 2019 - 09:36

A sustainable fish farm floating off the shores of Singapore gives a glimpse of what it is like to produce seafood with less energy and cleaner water, as the Government aims to reach the goal of producing 30 per cent of the country’s nutritional needs by 2030.

Situated 5km away from Changi Point Ferry Terminal, the facility called Eco-Ark looks to be one of the first floating closed-containment fish farms in the world, its developer said.

Built and run by Singapore food producer Aquaculture Centre of Excellence Group, it uses patented technology to rear three types of fishes for consumers here: Barramundi, red snapper and hybrid grouper.

Around 30 tonnes of fishes are housed in four cultivating tanks, each with a capacity of 475,000L, and they live in an environment where a filter system works round the clock to minimise bacteria, pathogens and waste.

Compared with fishes from coastal farms which are held in net cages and submerged in the sea, they are not vulnerable to changes in water temperatures, oxygen levels, bacteria levels, as well as oil spills, for instance.

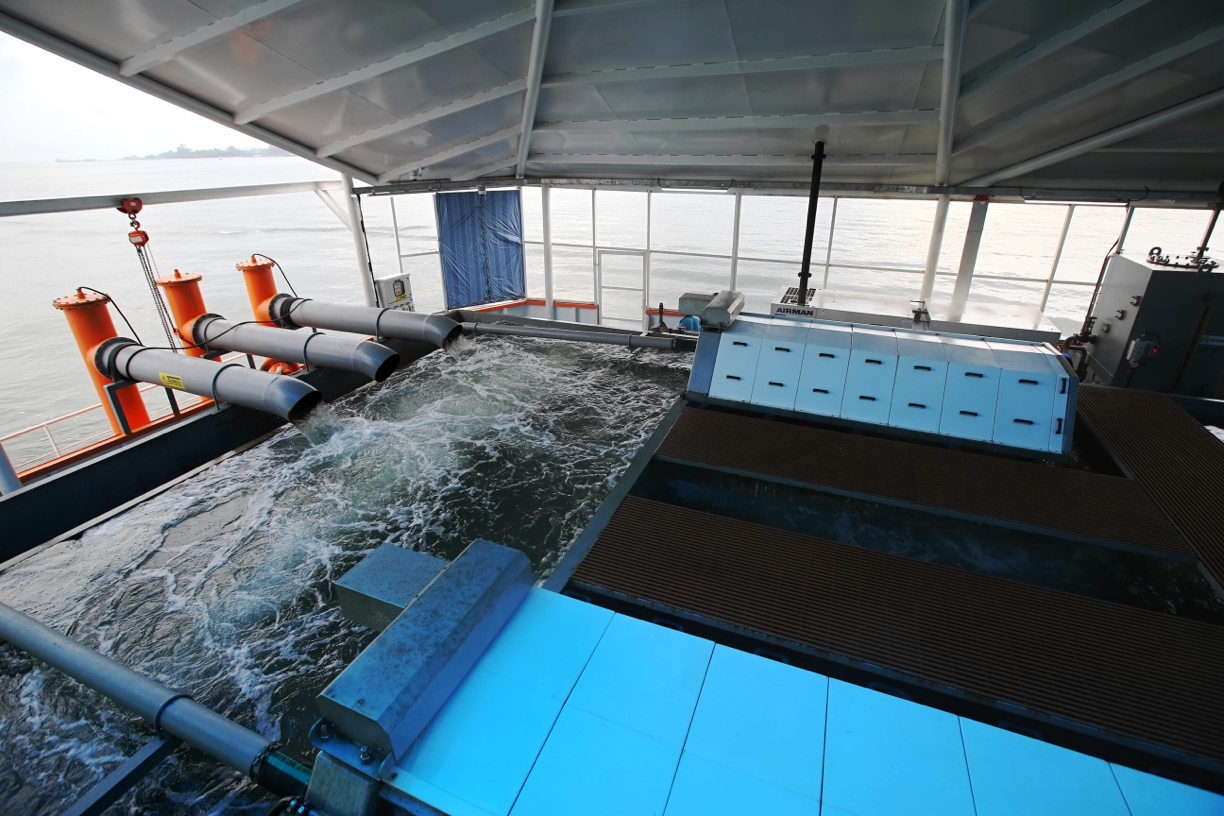

A view of the cultivation tanks where some 30 tonnes of fishes such as barramundi and red snapper are reared on the floating farm.

The Singapore Food Agency (SFA) said that there are 112 coastal fish farms here. Three of them, including Eco-Ark, are closed-containment farms and 109 are traditional net farms.

These farms produced about 4,600 tonnes of fish last year, accounting for about 9 per cent of fish consumption in Singapore — 15kg of fish was consumed per capita last year.

Eco-Ark, which cost S$4 million to set up and will be fully operational in three months, is set to generate a higher yield of fish within a smaller space than other coastal farms.

It can produce 166 tonnes of fish a year — 20 times more than the minimum production level set for each coastal farm by the authorities.

Yet it takes up just 1,400sqm of space — or one-fifth the size of a football field — which is about 14 per cent of the area taken up by a coastal fish farm with the same production capacity.

Speaking at the commissioning ceremony on Tuesday, Dr Koh Poh Koon, Senior Minister of State for Trade and Industry, said that Singapore needs to tap technology and innovative solutions to meet its goal of increasing food production locally.

Eco-Ark was built to achieve recommendations by SFA for farms to adopt new technology that will increase the amount of fish production and reduce the environmental impact to sea waters, he added.

“(It) allows us to conduct fish farming in Singapore waters more sustainably and this solution will be enticing and attractive to export to other parts of the world as well.”

Water is pumped in from the sea and filtered on the Eco-Ark.

The farming process at Eco-Ark consumes less energy than coastal farms or other closed-containment farms located on land.

For instance, every hour, there are three pumps each supplying 750 cubic metres of sea water and running at 17 kilowatts an hour. This is significantly lower than the land-based multi-tiered recirculation aquaculture system — a form of closed-containment farm — which may use up to 150 kilowatts an hour.

Mr Leow Ban Tat, chief executive officer of Aquaculture Centre of Excellence, attributed its efficient use of energy to patented technology which works on the differences in water pressure and gravity to pump water into the tanks.

Once pumped in, the water is put through a filtration chamber to remove solid particles.

It then goes through a process where dissolved oxygen is injected into the water. This makes it as clean and clear as waters in the ocean, and also removes pathogens and germs.

When the water eventually reaches the cultivating tanks that hold the fish, the level of dissolved oxygen is adjusted to suit the type of fish being reared.

Mr Leow added that due to this “ozonation” process carrying dissolved oxygen, the waste water that is later discharged from the tanks into the sea is also cleaner than when it was first pumped into the farm.

A worker cleaning the fish tank.

To reduce its use of energy, Eco-Ark — operating at 120 kilowatts a day — acquires one-sixth of its energy through solar power, which translates into S$80 savings a day.

At maximum capacity, the solar panels can generate power at 88 kilowatts an hour, Mr Leow said.

While he did not specify a schedule, Mr Leow hopes to eventually open two more Eco-Arks: One with eight tanks and another with 10 tanks. He did not say where these would be, but his goal is to set up an Eco-Ark farm in every country.

Source : TODAY