Energy Use in Aquaculture Pond Aeration Part 1/2

| Wed, 08 Jan 2020 - 10:20

Types of aerators, fuels and electric motors

Globally, most farmed shrimp is produced in mechanically aerated, outdoor ponds.

Mechanical aeration is a major component of energy use in shrimp farming. Around 4 million metric tons (MT) of the roughly 5 million MT of farm-reared penaeid shrimp in 2016 were from mechanically aerated ponds. The amount of aeration used in shrimp ponds has not been carefully studied, but shrimp farm managers often use a “rule of thumb” that each 300- to 500-kg increment of shrimp production requires 1 hp of aeration (3.33 to 2.0 hp/MT shrimp). Up to 1.5 MT/ha of shrimp can be produced without aeration, but this quantity usually is not subtracted from the production goal in calculating the aeration rate in order to allow a safety factor.

Determination of aeration rate from practical experience is not exact, but the complexity of dissolved oxygen budgets in aquaculture ponds makes it impossible to accurately calculate the aeration rate using equations based on hourly oxygen demand of the water, aerator oxygen transfer efficiency, minimum acceptable dissolved oxygen concentration, and water quality characteristics as done for wastewater treatment basins. Practical experience and monitoring of dissolved oxygen concentration remains the common ways of deciding how much aerator horsepower to install in ponds and for establishing schedules for daily aerator operation.

Small, electric motors use about 1 kWhr (a kilowatt-hour is a unit of energy equal to 3.6 megajoules) electricity per horsepower-hour of operation. The amount of energy used per MT of shrimp at an aeration rate of 2.5 hp/MT shrimp with aerators operated in ponds for an average of 16 hours a day during an 80-day grow-out period is quite large. Amounts of electricity (and energy) per hectare will increase steadily as production goal in MT per hectare increases, but the amount of energy applied per MT of shrimp for aeration is 11.5 GJ/MT (2.5 kW/MT ×16 hours/day × 80 days/crop × 0.0036 GJ/kWhr; GJ = gigajoule, a unit of measurement of energy) and constant across all production intensities.

An Asia-style, small, electric, floating paddlewheel aerator.

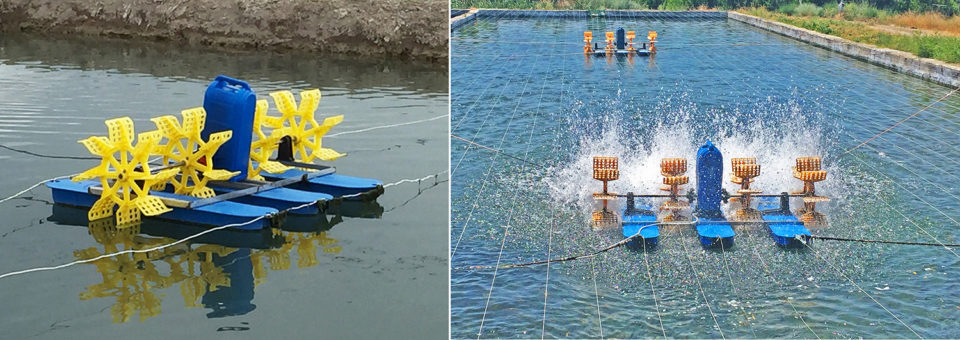

There are several types of aerators; different methods of powering aerators; and energy efficiencies of motors, engines and drive trains differ. The experience-based rule for aerator rate mentioned above was developed years ago in Asia for small 1- or 2-hp floating, electric paddlewheel aerators (image 1 below) that were widely used in shrimp ponds and for 1- to 2-hp propeller-aspirator-pump aerators (image 2 below) that also have received appreciable use in shrimp farming. Over the years, shrimp farmers have learned to fabricate and use less expensive, but also less efficient versions of factory-manufactured aerators. A discussion of the factors influencing the efficiency of energy use in shrimp pond aeration is overdue.

Aerators often are powered by electricity supplied by national or regional grids. Electric generators, usually powered by diesel engines located onsite, may also provide electricity for aeration. Fuels differ in energy content (Table 1) and energy also is used to produce these fuels. The total energy use incurred for fuel is its energy content plus the amount of energy required for its production (embodied energy). Total energy use may be estimated by multiplying the amount of each fuel used by the embodied energy factor for that fuel (Table 1).

Boyd, aeration Pt. 1, Table 1

|

Fuel |

Energy content (1) |

Embodied energy factor |

|

Ethanol (E100) |

21.27 MJ/L |

1.49 (2) |

|

Ethanol (E85) |

22.58 MJ/L |

1.34 (3) |

|

LPG (liquid propane gas) |

23.48 MJ/L |

1.12 (4) |

|

Gasoline (no ethanol) |

31.80 MJ/L |

1.36 (4) |

|

Gasoline (10% ethanol) |

31.25 MJ/L |

1.37 (3) |

|

Biodiesel |

33.32 MJ/L |

1.69 (5) |

|

Diesel (No. 2) |

35.80 MJ/L |

1.28 (4) |

|

Electricity |

3.6 MJ/kWhr |

2.50 |

Table 1. Energy content (lower heating value) of common

fuels and factors for including embodied energy in fuel energy calculations.

1: https://afdc.energy.gov/fuels/fuel comparison_chart_pdf.

2:

http://large.stanford.edu/courses/2014/ph240/dikeou1/docs/ethanolnetenergy.pdf

3: Calculated.

4: http://www.iea.org/statistics/resources/manuals/

5: https://.adfc.energy.gov/files/pdfs/3229.pdf

The energy contents of fuel allow determination of the volumes of each fuel necessary to provide the same amount of energy at a specific motor or engine efficiency. For example, 1.68 liters of fuel-grade ethanol (E100) would be required to obtain the same amount of energy provided by 1.0 liter of No. 2 diesel fuel (35.80 MJ/L diesel fuel ÷ 21.27 MJ/L ethanol = 1.68; MJ = megajoule, a unit of measurement of energy). Likewise, 9.94 kWhr of electricity represents the same amount of energy as does 1 liter of No. 2 diesel fuel.

Electricity generating plants convert primary energy in coal and other primary fuels with an efficiency of around 40 percent, and there is an additional loss of about 7 percent of the original primary energy in transmission of electricity through the grid – overall efficiency of about 33 percent. Larger generators are more efficient than smaller generators in converting the energy of diesel fuel to electricity (Table 2), but larger units are only 35 to 38 percent efficient, and additional losses will occur in transmission to aerator motors.

Boyd, aeration Pt. 1, Table 2

|

Rated output (kW) |

Fuel use at 75% load (L/hr) |

Energy output at 75% load (% input) |

Energy output at 75% load (kW/L) |

Energy output at 75% load (MJ/L) |

|

25 |

7.00 |

26.9 |

2.65 |

9.65 |

|

50 |

13.25 |

28.4 |

2.83 |

10.19 |

|

100 |

21.95 |

34.3 |

3.42 |

12.31 |

|

150 |

31.79 |

35.4 |

3.54 |

12.74 |

|

200 |

41.64 |

36.1 |

3.60 |

12.96 |

|

250 |

51.48 |

36.5 |

3.64 |

13.10 |

|

500 |

99.92 |

37.6 |

3.75 |

13.50 |

|

750 |

148.75 |

37.9 |

3.78 |

13.61 |

|

1,000 |

197.20 |

38.1 |

3.80 |

13.68 |

Table 2. Typical fuel use and energy output for different

sizes of diesel-powered generators.

Source: https://www.dieselserviceandsuply.com/Diesel_Fuel_Consumption.aspx.

Energy efficiency from primary fuel is roughly equal for electricity from the national or regional grid and from onsite generators. The cost of primary fuels per kilowatt-hour generated is less for large power plants than for smaller diesel generators and grid electricity usually is less expensive than electricity generated at shrimp farms.

Next Page of The Article: Energy Use in Aquaculture Pond Aeration Part 1/2