A Short History of Aquaculture Innovation

| Wed, 16 Sep 2020 - 12:33

Humans have manipulated marine and freshwater habitats for millennia. Early Indigenous peoples around the world showed ingenuity and an acute awareness of how ecosystems worked as they found ways to encourage more bountiful harvests of all kinds of aquatic life. But we’ve taken a sharp turn away from the simple elegance of a clam garden or a fish trap and veered toward industrial mechanisms for domesticating aquatic species.

Farming fish and shellfish dates to ancient China, Egypt, and Rome, but the pace of innovation—especially when it comes to raising marine species—accelerated in the last century with modern technologies. Today, the Food and Agriculture Organization of the United Nations (FAO) says aquaculture is growing faster than other major food-production sectors.

Innovations come through many avenues—scientific research, novel materials (what a difference plastics made), and float and net technologies. Notably, the salmon farming industry has led many breakthroughs, evidence that when there’s money to be made by creating and marketing a high-end product, investments in technology tend to follow.

Here’s a brief overview of the research and technologies that have made today’s food revolution blue.

1883

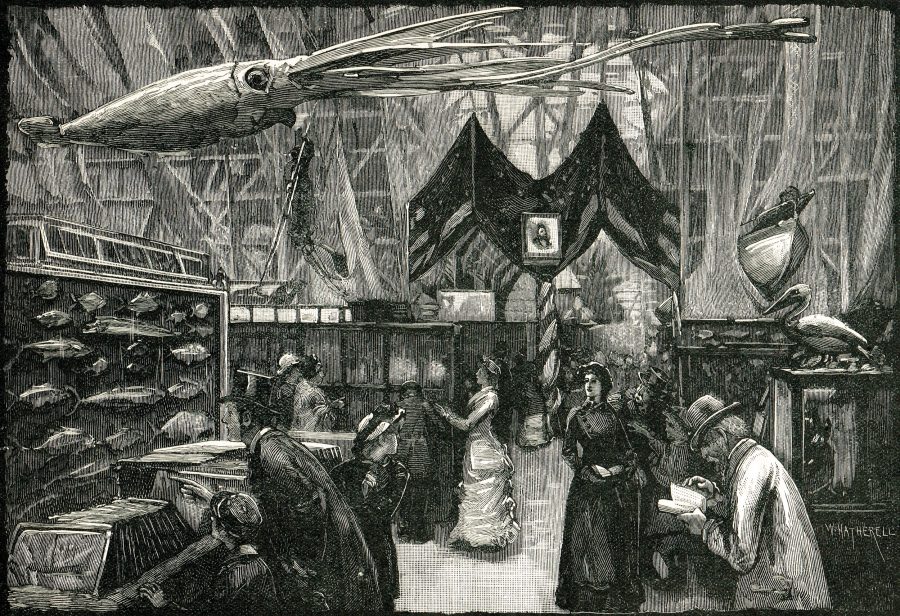

Illustration of the International Fisheries Exhibition of 1883

The 1883 International Fisheries Exhibition in London, England, included an exhibit from the United States, shown here. Photo by Historical Images Archive/Alamy Stock Photo

The 1883 International Fisheries Exhibition, which ran from May through October in London, England, featured all things related to fishing and fishermen, and also highlighted a growing interest in culturing species including salmon, trout, and oysters. The event was hugely popular—with 25,000 people passing through the turnstiles on one May day alone. While most visitors were likely happy to simply enjoy the aquariums, military bands, and fish dinners, those interested in learning about the weightier goals of the exhibition could peruse the almost 400-page official catalog. One section stated that the object of modern pisciculture was, in part, to restore already depopulated waters. The writer expressed hope that information collected and distributed through the exhibition would serve to “make an acre of water more valuable than an acre of land.” Exhibition prizes were available in a number of categories related to fish culture, such as the best description of fishpond construction and management. A Scottish landowner was among the attendees who presented research, explaining that pure water and rat-proof drains were necessities for success. Fish culture, he said, not only involved the artificial propagation of fish, but also producing their food and getting them to market, “just as much as the culture of corn is understood to mean not merely the sowing, but every step from the preparation of the seed bed to the marketing of the harvest.”

1899

Oscar II, King of Sweden and of Norway

Oscar II, King of Sweden and Norway, welcomed delegates to a scientific conference to discuss the ocean and fisheries in 1899. This and subsequent conferences led to the creation of the International Council for the Exploration of the Sea. Photo public domain

In Western countries, a growing concern that fish stocks were declining led to the establishment of marine laboratories and fish hatcheries. The Swedish government invited delegates from a handful of countries to attend a scientific conference dedicated to ocean research and how it related to the fishing industry. This and subsequent conferences, including one in Kristiania (now Oslo), Norway, resulted in the participating countries founding the International Council for the Exploration of the Sea. Delegates planned both hydrographical and biological studies, which included keeping records of salinity, currents, and temperature, as well as investigating the life histories of economically important fish. These internationally coordinated efforts boded well for the advancement of oceanographic research, but with fish hatcheries dogged by difficulties—including those associated with running mechanical water systems and a failure to understand the feeding requirements of fish larvae—this enthusiasm did not translate into much momentum in the field of aquaculture.

1924

Tilapia was first cultivated in ponds in Kenya. Nicknamed “the aquatic chicken”—because, like the popular fowl, it’s an economical source of mass-produced, mild-flavored animal protein—tilapia is disease-resistant, grows quickly, and tolerates poor water quality, making it a popular choice for both subsistence and commercial production in many countries. The challenge: this fish breeds early and often, which leads to overcrowding, competition for food, and stunted growth. By the 1970s, researchers had devised a solution: sex reversal technology, which produced all-male populations through hormone manipulation. (Males were preferred because they grow faster.) This advancement was one of several that facilitated the growth of the tilapia industry. According to the FAO, in 2017, tilapia was the most popular aquaculture species group in 127 countries. And Nile tilapia was ninth on the global list of top aquaculture species based on production quantity (measured by live weight)—not bad for a chicken.

1927

oyster farm

This oyster farm in Chanthaburi, Thailand, uses a technology that has changed little in almost 100 years. Photo by Tanes Ngamsom/Alamy Stock Photo

In Japan, Hidemi Seno and Juzo Hori published a paper describing their new method for growing oysters by attaching them to ropes and hanging them vertically from a floating raft. The innovative method replaced a 300-year-old tradition of driving bamboo sticks or tree branches into the ground in shallow water to provide a surface on which free-swimming oyster larvae could settle. Vertical suspension allowed oysters to take in more food and grow faster, as they could feed even when the tide was out. Oysters grown above the seafloor were also safer from predators and produced higher-quality meat. People were quick to adopt this new method, and the production of cultured edible oysters in Japan tripled in about 10 years. By 1958, it was reported that over 90 percent of the oysters produced in Japan were grown using the hanging method.

1933

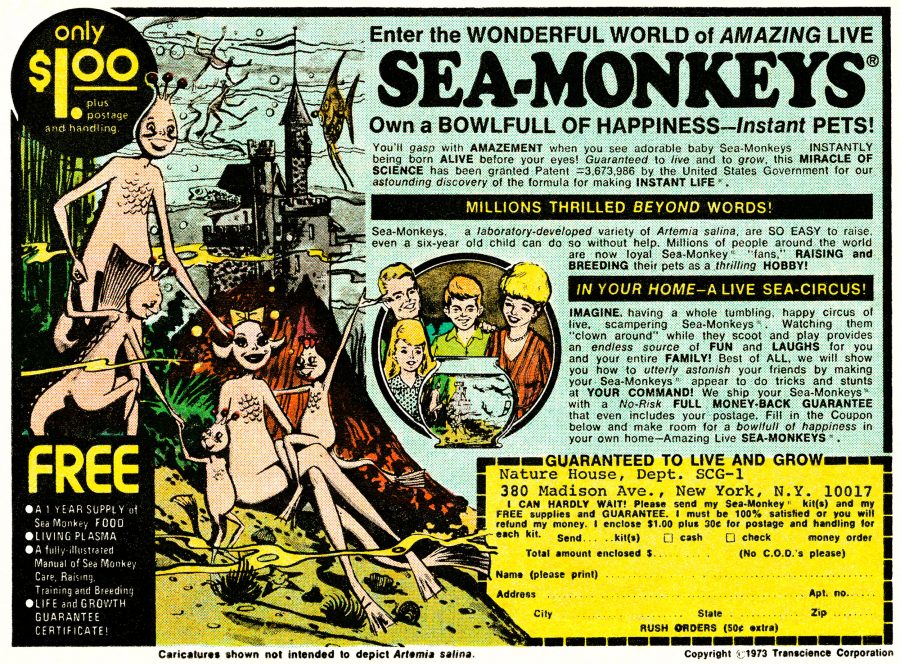

Ad for sea monkeys

A 1975 advertisement for Sea-Monkeys, aka brine shrimp. Although probably not really a “bowlfull of happiness,” once the tiny creatures hatched in the homes of those willing to fork over a dollar for a “live sea-circus,” they were excellent food for larval fish. Photo by M&N/Alamy Stock Photo

Alvin Seale, superintendent of the Steinhart Aquarium in San Francisco, California, discovered that the brine shrimp Artemia made an excellent food source for fish larvae. Young marine fish at the aquarium typically ate live food such as plankton, which was not easy to mass produce. Seale noticed that the fish thrived when fed tiny crustaceans harvested from nearby salt ponds. Artemia—a hybrid of which was later sold as the novelty instant pets called Sea-Monkeys—soon became a dietary staple for the aquarium’s animals. But they were hard to source in the winter, so Seale visited the salt ponds to gather sand-grain-sized Artemia eggs and started experimenting. When conditions such as temperature or salinity levels are unfavorable, females encyst their eggs, which can stay dormant until conditions improve. Seale wrote that these cysts could remain viable almost indefinitely and concluded that it was possible to have a good supply of live food by simply triggering the eggs to hatch when needed. Dried and canned, this food was available year-round, it was easy to store and prepare, and it had a long shelf life. Artemia remains an important food source for the larval stages of commercially farmed marine fish and shellfish.

1950

By the 1950s, a sea change was underway as plastics revolutionized the design and manufacture of many items in the aquaculture industry. Salt water is bad news for aquaculture operations—it corrodes pipes and valves, leaching heavy metals into the water, which can poison fish, and makes the upkeep of mechanical systems expensive and time-consuming. While the first fully synthetic plastic was developed in 1907, it wasn’t until after the Second World War that the large-scale manufacturing of plastics really took off. In their 1963 paper about rearing bivalve mollusks, Victor Loosanoff and Harry Davis of the Milford Laboratory in Connecticut noted finding an increasing use for plastic pumps and pipes, although they said that plastics could be contaminated by chemicals, including insecticides. Possible disadvantages aside, the development of aquaculture has been dependent on the use of plastic. Today, plastics are found in many items, including fish cages, pond linings, and seafood packaging.

1954

Researchers at the Oregon Fish Commission and what is now Oregon State University developed a fish food in a moist, soft pellet form as a replacement for the more traditional diet of dry grains and meat. The pellet formula varied over the years. In 1956, frozen tuna viscera, herring meal, cottonseed oil meal, corn oil, folic acid, and niacin were among the ingredients. Antibiotics and additional vitamins could also be added to the pellets. At a conference in 1960, Wallace F. Hublou of the fish commission said that the pellets had been fed to steelhead and several species of salmon. After almost two years of production use, the pellets were living up to expectations—not surprising as the cost to produce a kilogram of fish was 41 percent less than in 1958 before pellet feeding. Cost was not the only advantage: Hublou reported that pellets took up less storage space, eliminated the need for food preparation in the hatchery, and caused less water pollution than traditional feed, which also cut labor requirements as less pond cleaning was necessary. While formulations continue to evolve, pelleted feeds remain an aquaculture staple.

1958

Japanese scientist Motosaku Fujinaga, who had first artificially spawned and hatched kuruma shrimp in a tank in 1933, continued to build on his success by producing 10 kilograms of shrimp big enough to be marketable. The quantity may have been modest, but the exhaustive research they represented was impressive. By 1967, Fujinaga was able to produce 1.5 million fry in a 10-by-10-meter concrete tank, and he reported that there were 11 kuruma shrimp culturing sites in Japan producing 200 tonnes of shrimp annually. At a scientific conference in Mexico, he explained that the scale of operations had been greatly increased and the cost of production lowered by using large outdoor tanks filled with seawater. His techniques, including the use of the brine shrimp Artemia as a food source, gave rise to the modern shrimp farming industry. Fujinaga, often called the father of shrimp farming, believed the shrimp cultivation industry could contribute to solving what he called the growing problem of protein shortages.

1959

Norwegian brothers Karstein and Olav Vik built floating wooden cages with suspended nets to hold their Atlantic salmon and moved toward establishing ocean-based fish farming. The Viks had started their experimentation with freshwater trout a few years earlier, trying to see if the fish could acclimate to life in salt water, a habitat that was thought to speed up growth and reduce the risk of disease. They proved it was possible and then began experimenting with Atlantic salmon, an anadromous species that migrates between fresh water and sea water. By manipulating salinity levels and using their open-ocean floating cages, they were able to raise salmon from eggs to adults completely in captivity. The US patent for their method of breeding fish—which they claimed could almost double the fish growth rate—was granted in 1968. As Norway’s wild fish stocks starting collapsing in the 1960s, the country eagerly embraced the possibilities of this new industry, and today Norway is the world’s largest producer of farmed Atlantic salmon.

1963

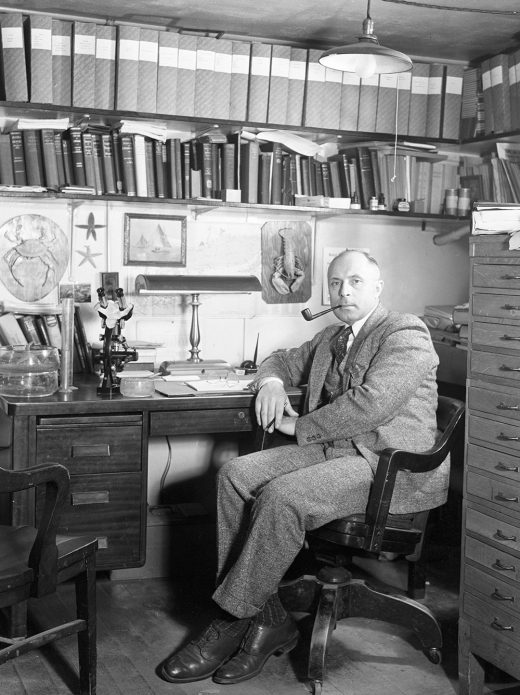

Victor Loosanoff

Victor Loosanoff and his colleagues at the Milford Laboratory in Connecticut made many contributions to our understanding of shellfish biology and reproduction. This included developing methods to spawn bivalves nearly year-round. Photo courtesy of NOAA Fisheries

Victor Loosanoff and his colleagues at the Milford Laboratory developed techniques for making bivalves spawn almost year-round, allowing researchers in seasonal climates to experiment with rearing shellfish outside the short periods of natural propagation. They stimulated the normal development of bivalve gonads and induced spawning by taking mollusks from outside where water temperatures might be near freezing, putting them into warmer water, and then gradually increasing the temperature. With their conditioning and rearing methods, the scientists successfully cultured about 20 species of bivalves at the Milford lab. Loosanoff published hundreds of articles, got credit for helping save the ailing North American shellfish industry, became known as the father of US shellfish hatcheries, and had a research vessel named in his honor. The techniques Loosanoff and his colleagues developed became known as the Milford method and are still used in shellfish aquaculture today.

1970

Off the island of Hitra in Norway, brothers Ove and Sivert Grøntvedt put 20,000 Atlantic salmon smolts into large floating octagonal cages they had designed and built. Inexpensive, strong, and simple to assemble, the cages made it easier to feed the salmon and created a barrier against predators. The brothers’ venture was regarded as the world’s first successful salmon farm. Their cage design combined with government support and Norway’s nature—a long coastline, protected waters, stable water temperatures—nurtured the Norwegian aquaculture industry. Norway exported 886 tonnes of salmon in 1971; in 2018, the country produced over 1.3 million tonnes of salmon. According to the Norwegian Seafood Council, 14 million meals of Norwegian salmon are eaten daily worldwide.

1971

Norwegian scientist Trygve Gjedrem believed the basic elements of breeding theory were the same for fish and shellfish as for farm animals. After researching topics such as sheep-fleece weight and wool quality traits, he turned his attention to salmon, helping develop the world’s first family-based breeding program for fish. The program was designed to produce high-quality, fast-growing Atlantic salmon with high disease resistance. The breeding program contributed to the success of Norway’s salmon aquaculture industry: by 2010, an estimated 97 percent of the world production of Atlantic salmon was based on genetically improved stock. Gjedrem later contributed to the Genetic Improvement of Farmed Tilapias project, which was initiated in the Philippines and developed faster-growing stocks of Nile tilapia for small-scale farmers and commercial operators alike.

1980s

recirculating aquaculture system

This ornamental fish nursery in Asia uses a recirculating aquaculture system. Photo by Roman Diachkin/Alamy Stock Photo

Denmark was one of the first countries to use recirculating aquaculture system (RAS) technology for commercial European eel aquaculture. Recirculating systems are now used to produce both fresh- and saltwater species, including rainbow trout, whiteleg shrimp, and turbot. With RAS, species are raised on land in a contained facility that recirculates and filters water so it can be reused. While high start-up and operational costs and the need for highly skilled staff have hampered widespread adoption of the technology, advantages include eliminating the possibility of farmed stock escaping into the wild and the ability to keep external conditions such as water temperature stable, which results in steady growth. The Monterey Bay Aquarium Seafood Watch’s “best choices” list includes several species farmed in recirculating tanks, a farming method that it says can minimize disease and the discharge of pollutants with wastewater treatment. Charoen Pokphand Foods of Thailand aims to produce all its whiteleg shrimp with indoor RAS by 2023. Other RAS ventures currently planned include a US $500-million Atlantic salmon farm in Maine that’s expected to produce about 30,000 tonnes of fish annually and a $152-million Atlantic salmon farm in Japan that will produce 10,000 tonnes of fish annually.

1999

At an experimental fish farm in France, researchers employed acoustic telemetry technology to measure fish swimming behavior. They fitted rainbow trout with miniature ultrasonic transmitters, and used hydrophones and specially developed software to show that monitoring fish activity was feasible in high-density culture conditions. Today, as aquaculture operations seek to feed and care for ever-increasing numbers of fish—a single Norwegian sea cage can hold up to 200,000 farmed salmon—the traditional methods of measuring parameters such as size by eye or by hand can be time-consuming and inaccurate. In addition to acoustic telemetry, methods for monitoring fish now include sonar and computer-vision technology, in which video from submerged cameras and computer-vision algorithms are used to gauge variables such as fish size and sea-lice infestation.

2018

Ocean Farm 1

Ocean Farm 1 is an offshore fish farm operated by a Norwegian company. Photo by Imaginechina Limited/Alamy Stock Photo

With companies increasingly recognizing the potential of offshore aquaculture, the Chilean venture Ocean Arks Tech obtained a patent for a self-propelled fish farm—basically a 170-meter vessel that can produce 3,900 tonnes of commercial fish species such as salmon, tuna, and amberjack. Billed as “aquaculture without borders,” this floating farming vessel will operate in the open ocean where it can seek optimal water conditions for fish production and avoid algal blooms and areas of low oxygen and acidity. While it’s possible that this idea for autonomous ocean aquaculture ends up dead in the water—at the time of writing, the company’s Twitter account had 22 followers—others have already set sail for the high seas: in 2017, Norwegian company SalMar began operating Ocean Farm 1, which it called the world’s first offshore fish farm. The pilot facility—68 meters high and 110 meters wide—was fitted with 20,000 sensors for monitoring and feeding up to 1.5 million Atlantic salmon. Meanwhile, in the Yellow Sea, China’s first deep-sea fish farm got underway in 2018. Located about 240 kilometers offshore, the 35-meter-tall structure can submerge as deep as 50 meters to reach the best water temperature for keeping the farm’s 300,000 salmon alive. A 2019 report by the Nature Conservancy and Encourage Capital, written in an effort to spark greater investment in sustainable aquaculture, identified offshore finfish aquaculture as one of three systems with the greatest potential for financial returns and improved environmental sustainability.

2020

Cermaq, a Norway-based fish farming giant, planned to launch its $63.7-million iFarm project with the goal of monitoring not just an entire cage of salmon, but each individual fish. Cermaq says iFarm sensors recognize individual salmon based on their dot pattern, which makes it possible to keep track of the number of fish, fish size, number of sea lice, and possible signs of disease. Meanwhile, Norway Royal Salmon, Microsoft, and technology company ABB piloted an artificial intelligence system to monitor salmon in offshore sea cages. The companies claim remote monitoring will mean workers are safer because they won’t be out on the open water as often, and that there will be an environmental advantage as fewer boat trips out to the sea cages to manually check the salmon will reduce carbon dioxide emissions. In a 2018 article in Biosystems Engineering, researchers said that because variables like fish numbers and fish size affect key decisions—for example, how much food and medicine is needed—being able to predict and quantify those variables has become “a holy grail in the salmon farming industry.” With operations aiming to produce ever-greater quantities while grappling with challenges such as securing adequate and ecologically sustainable feeds and competing for space with other industries, the authors say that future fish farming methods will need to be smarter. In other words, more outside-the-sea-cage thinking will be required to move the industry forward into its next era.