Shrimp, Pangasius Next After RAS Tilapia Product Trial More Than Triples Productivity in Ponds

| Mon, 09 Dec 2019 - 16:30

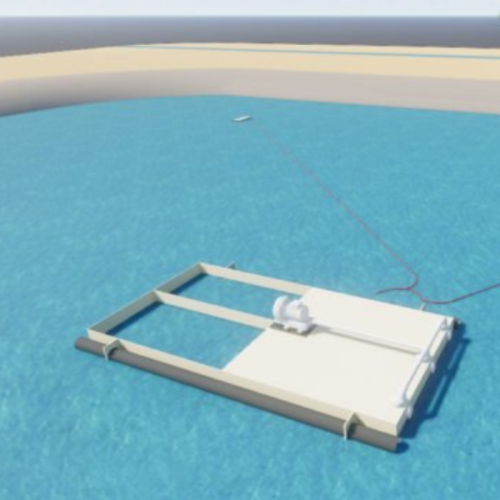

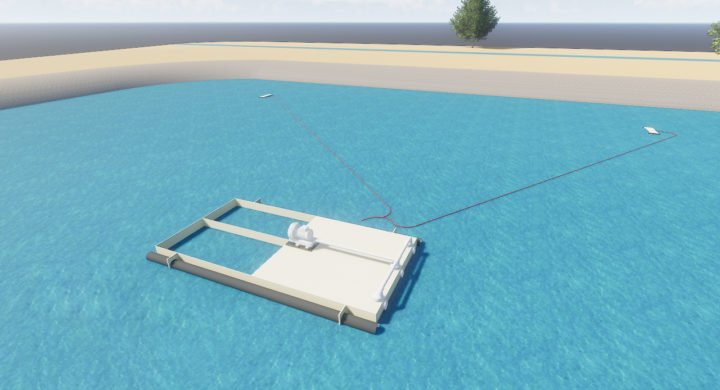

The MARES project MVP design

The first commercial-scale trials of a new recirculating aquaculture system (RAS) technology in Vietnam have produced strong results for tilapia farmers, project organizers Fresh Studio and Alpha Aqua told Undercurrent News.

Tested with tilapia for its "greater robustness and the wide availability of references in literature", the next stage of the technology's developments will be designed for use in shrimp and pangasius ponds -- Vietnam's most economically important aquacultured species -- they said.

The device in question is a water treatment "box" which floats in ponds, acting as a "third lung" and increasing carrying capacity and ecosystem stability. In the trial, three control ponds were stocked at three fish per-square-meter, while the treated ponds were stocked at 15 fish per meter square -- the reference for the prototype's design capacity.

"With the application of the prototype technology the productivity in the treatment [ponds] reached 16.92 [metric] tons [per hectare, per crop]. The productivity was therefore multiplied by a factor of 3.8 compared to the controls, in which the productivity reached 4.5t/ha/crop," said Fresh Studio and Alpha Aqua in a report developed for the Dutch ministry of agriculture, nature, and food quality, which often funds aquaculture improvement programs.

The average survival rate in the prototype's ponds was 82.4%, compared with 79.3% in the controls. Average feed conversion ratio (FCR) was 1.36, 8.2% lower than in the controls. Boiled to the simplest and, perhaps most important number; the prototype meant $0.19 extra profit per kilogram of fish harvested.

These benefits are meaningless if the prototype is not affordable to the average Vietnamese farmer for whom it is designed, and this was the forefront of the development process.

Based on the prototype's performance -- which has prompted Fresh Studio and Alpha Aqua to begin work on several improvements already -- they expect farmers would spend $3,500 per 500-meter-square pond, and could break even in under four years. Over 10 years, farmers should be able to multiply revenues from their farms by a factor of 50, they estimate.

On top of this, improvements to the initial design could bring break-even point down from four years to just two. Made of recycled plastic, the creators estimate the device should last for up to 30 years.

"We're happy with the initial trial results, in terms of affordability," Alban Caratis of Fresh Studio told Undercurrent. "When you consider FCR alone, using 8% less feed [which makes up between 50% and 70% of farmers' expenses] should mean significant savings. And that's before improvements."

What next for the project?

This "minimum viable product" will be followed up by a "minimum marketable product" (MMP), to be developed and piloted at a commercial scale with two groups of farmers in the Mekong Delta.

One will focus on integrating the MMP in a "service delivery model" for small-scale intensive shrimp farmers, while the second will focus on integrating it for pangasius nurseries, "which will grow high-quality fry produced in an indoor and fully controlled hatchery system developed by Alpha Aqua and Fresh Studio".

This will, therefore, be developed with the intention of applying the technology to pangasius nurseries and intensive shrimp farming systems on a wider scale.

In the meantime, the Mekong Aquaculture Solutions, or MARES, the project -- backed by the Dutch government -- will run demo days across the region in a bid to raise acceptance of new technologies.

"In January we'll start those demos," Caratis told Undercurrent. "We'll gauge interest, get some critical feedback, and -- we hope -- find a small number of early adopters who'll want to work with us in developing the technology."

The aim is to bring these farmers into a program through which MARES will sell or lease the technology, as well as provide ongoing training and support services to shrimp producers.

Then, when it comes to more extensive commercial trials of the updated design, these farmers will put the MMP to use for a year or two, capturing performance and economic data. "We hope these early adopters can become like our ambassadors, and that we will be able to use their farms in the future for further demos" said Caratis.

The project is looking at a conservative, long-term timeline, illustrating Alpha Aqua's desire to be a partner to the Vietnamese a sector, and not simply "drop some tech and run," said the firm's COO for veterinary and biological farmer expertise, Ramon Perez.

Work with pangasius nurseries has already begun, the pair revealed.

"The jump from tilapia to pangasius was fairly easy to make," said Caratis. "We're working with pangasius nurseries because that's such a key area in need of improvement in Vietnam." The project is working with Can Tho University and its students at some of the earliest open days.

Source: Undercurrent News