Swedish Innovators Create Multiple Revenue Streams From Effluent

| Wed, 06 May 2020 - 09:25

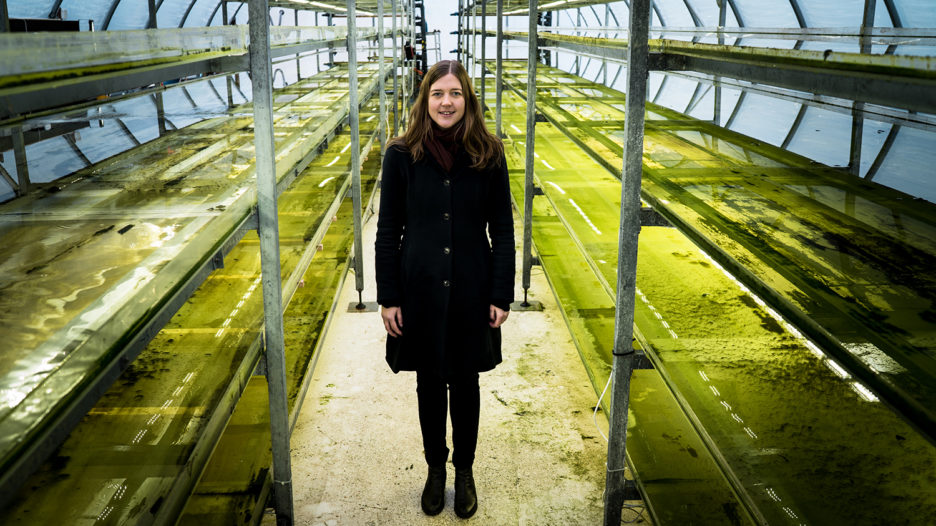

Swedish Algae Factory Co-founder Sofie Allert (above) and Angela Wulff began a research project studying algae that thrive in cold, dark climates and found a particular strain that was thriving in Sweden. Photos courtesy of Swedish Algae Factory.

Swedish Algae Factory (SAF), a Gothenburg, Sweden-based company, is using effluent water to harvest an algae with multiple uses and diverse revenue streams. In demand by the personal care, solar industry and as an ingredient for fish feed and fertilizer, the company’s high-value product, Algica, is created from the nutrients exiting recirculating aquaculture systems (RAS).

SAFs latest round of funding raised €5 million, a large portion of which came from Aqua-Spark, the investment fund for sustainable aquaculture. This investment will allow SAF to build a large-scale algae factory in Europe to further its research and development of Algica.

Co-founders Sofie Allert and Angela Wulff met at the Chalmers School of Technology in 2014. Allert, the 29-year-old CEO of SAF, studied biotechnology and was interested in growing algae in Sweden, while Wulff, a part-time professor, had studied algae thriving under the ice in the Antarctic. The pair began a research project studying algae that thrive in cold, dark climates and found a particular strain that was thriving in Sweden.

Their goal was to have that algae utilize otherwise-wasted nutrients in fish manure to create a product that was climate positive and environmentally friendly. When they were approached by Smogenlax, Sweden’s only saltwater, land-based fish farm, they realized they had the perfect opportunity to create a pilot algae farm, growing algae by using nutrients in the effluent water from the RAS facility before that water entered wastewater treatment.

“We understood that this would be good for us and Smogenlax, so we agreed not to talk, but instead to start testing,” Allert said. “We built a 24-square-meter greenhouse close to the farm and a system wherein the fish farm effluent water flowed through our algae cultivation before it entered wastewater treatment, so we could filter out the nutrients and make use of them.”

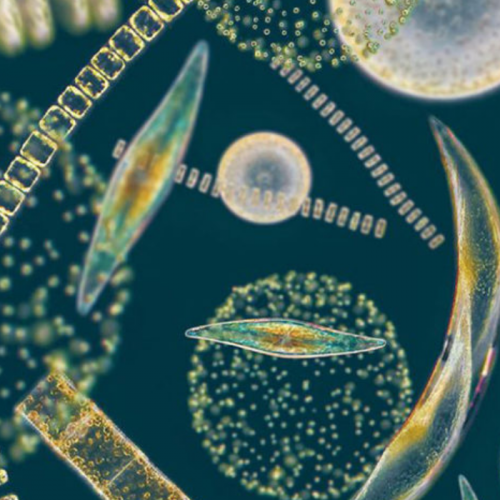

Over the next two years the two entrepreneurs learned that different parts of the algae were useful to various industries. Algica, the silica shell of the algae, has value as an ingredient in the personal care industry, while its light manipulating properties can enhance the efficiency of solar panels up to 4 percent. Inside that silica shell is a biomass rich in omega-3 fatty acids, carbohydrates and proteins that can be used as fish feed and fertilizer.

The algae doubles itself daily and right now its harvesting process takes up to two weeks. With their investment funding Allert and Wulff are planning the construction of a larger facility on a bigger fish farm that will enable them to increase their annual Algica production from 30 kg to 1 ton.

“Algica is very porous so density is very low,” Allert said. “You need 0.02 grams of Algica per square meter of solar panels, while in personal care products you use 0.1 grams of Algica per 100 mL of formula.” Algica is sold by the gram, while its fish feed or fertilizer byproduct is sold per kilo.

More testing is required before Algica can be used in the solar panel industry, but Swedish Algae Factory is already supplying Algica to small- and medium-size customers in the personal care industry in Sweden, Finland and South Korea. “The Algica will be our biggest source of revenue and by selling it to personal care and solar clients we can sell its byproduct as fish feed and fertilizer,” she said.

“The main demand for Algica right now is in personal care products but I think once the solar panel testing is completed we will be selling to personal care and solar industries equally. The material we’re producing for both is the same, so we won’t need to modify our production, and will be able to supply both industries from the same farm.”

The new algae factory will cost €4 to €5 million and Allert said there are a few site options under discussion.

“The fish farmers we’re talking to are happy to have us on site because we help them lower the cost of their effluent treatment,” she said. She is hopeful the factory will be ready by December 2021 and anticipates rapid expansion with new algae factories on other fish farms.

The Algica product is created from the nutrients exiting recirculating aquaculture systems.

The expansion possibilities are thanks to an additional €2.2 million the company received in grant funding from the European Union and the Swedish Energy Agency, and the €500,000 it won in the Postcode Lotteries Green Challenge last year.

Mike Velings, co-founder of Aqua-Spark, said he was impressed by how SAF is solving a major issue for land-based aquaculture and sustaining a separate, diversified business model: “We are really excited about this fully female-founded company and the algae they are growing and we think it has great potential,” he said.

“SAF is creating a really good solution, using run-off from fish farming operations and turning it into a valuable product. We love the circular approach because it shows how you can do more with the systems the aquaculture industry is building across the globe. We think algae can be a much bigger part of the future than it is now. For today, we’ve just scratched the surface, but we hope to get a better understanding over time.”

The company has made heady progress since its 2016 inception and Allert said that can be daunting at times.

“What drives me, though, is making a positive impact in the world, and my way of doing that is through algae,” he said. “I’m grateful and happy to have people around me that believe in our vision: to use alga to create a positive impact in the world.”

Source: Global Aquaculture Alliance