RAS Disinfection Strategies

| Thu, 18 Mar 2021 - 09:30

Disinfection is an important component of any aquaculture facility’s biosecurity protocols, as it plays a critical role in minimizing the likelihood of pathogen entry and spread within fish farms. Despite a consensus among producers regarding the overall importance of disinfection, and the availability of several published recommended guidelines, there is a general lack of documentation on the current status of disinfection strategies in aquaculture.

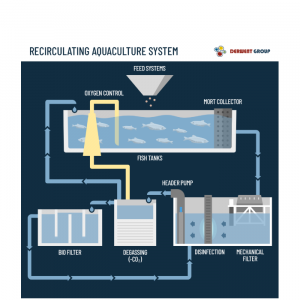

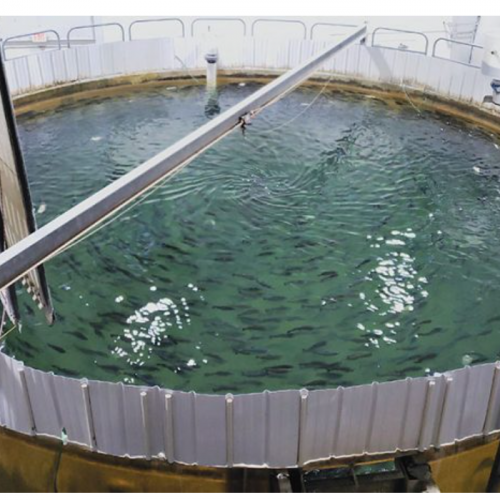

This is particularly relevant in salmonid aquaculture, in which production technologies have advanced significantly in recent years. For example, many Atlantic salmon facilities are intensifying production by adapting recirculating aquaculture system (RAS) technologies during the land phase of the production cycle, which is a significant shift from traditional flow-through or partial water reuse systems.

To gain insight into the present status of disinfection strategies at such facilities, a survey was conducted targeting selected salmonid producers in Norway and North America. The questionnaire covered key aspects of disinfection of materials and equipment in a RAS facility, including: general information about the disinfection protocols, information on the disinfectants in use, disinfection protocols of tanks and pipelines, disinfection of ancillary equipment, floor disinfection, disease outbreaks, and health and safety of staff. The facilities were selected based on their known use of land-based RAS technologies.

Also read: Polyculture Of Pikeperch Juveniles in Recirculating Aquaculture Systems

The survey did not specify the type of RAS technology being used in each site, was limited only to disinfection of materials and equipment, and did not include water disinfection.

While it is not feasible to present all survey results in this short article, some interesting information was revealed regarding different disinfection strategies currently in use by major land-based RAS salmonid producers in Norway and North America. Some of the key similarities among the facilities between the two regions include the following: while the majority of facilities possess standardized disinfection protocols, disinfection efficiency has generally not been experimentally validated; the majority of facilities continually appraise their disinfection protocols, which highlights the dynamic nature of disinfection practices in RAS operations;

when selecting disinfectant types, efficacy against pathogens and user safety are the most important criteria for producers; different disinfection approaches are used for different types of ancillary equipment, based on the actual equipment materials and specific disinfection requirements; although disease outbreaks within the past five years were uncommon among respondent facilities, immediate disinfection was carried out after each outbreak; and, facility staff are well-trained to carry out disinfection procedures, including proper use of protective gear and adherence to specific occupational health and safety guidelines.

Also read: Benefits of Recirculating Aquaculture Systems

Important differences between Norwegian and North American respondents were also revealed when assessing survey results. These differences included: most Norwegian facilities do not have a set of criteria in assessing cleaning, disinfection, and rinsing strategies, unlike in the majority of North American sites; peracetic acid and hydrogen peroxide are the most commonly used surface disinfectants in Norwegian RAS sites, whereas chlorine/sodium hypochlorite and quaternary ammonium compounds are most common in North America; and, there is significant variability between Norwegian and North American RAS producers regarding the specific practices for disinfecting tanks and pipelines, floors, and ancillary equipment, especially concerning the actual disinfectant used, and pre- and post-disinfection application and contact time, among other things.

Despite the limited number of sites surveyed, the range of respondents included those from all major salmon companies using RAS technologies. Therefore, it is likely that the survey data obtained provided a representative picture of how the current industry approaches facility disinfection. Overall, the information gained through this survey can be valuable not only for RAS producers, but also for policymakers and governmental entities, and can be used as foundational knowledge in benchmarking disinfection strategies. This, in turn, can support the eventual establishment of universal guidelines, particularly for producers utilizing RAS technologies.

Also read: A successful Case of Split Pond Recirculation Aquaculture System (SP-RAS) for Snakehead Fish Farming in Andhra Pradesh of India

For a more comprehensive summary of the disinfection survey results, the full peer-reviewed article is available as an open access publication and can be downloaded, free-of-charge, from the Aquaculture (Elsevier) website. The title of the article is: “Survey findings of disinfection strategies at selected Norwegian and North American land-based RAS facilities: A comparative insight” (Aquaculture, Volume 532). This study received funding from the Research Council of Norway and from the Centre for Closed-Containment Aquaculture (CtrlAQUA) (Project No.: 237856/O30).

The authors wish to extend their sincere gratitude to all survey participants for their time and effort in completing and returning the survey. We hope that our findings represent a first step towards the establishment of efficacious best management practices and standard operating procedures for disinfection approaches in salmonid RAS facilities, regardless of geographic location.

Source: Hatchery International