Montana Firm Putting Barley on The Alternative Feed Ingredient Menu

| Thu, 16 Jan 2020 - 10:17

The catalog of aquaculture feed ingredients that are used to create nutritious and cost-effective products, while conserving fishmeal and fish oil supplies have expanded in recent years. Many of these new alternative-ingredient innovations, however, face significant challenges in scaling production – think insect meals and single-cell proteins – and as a result haven’t yet impacted the sector like terrestrial agriculture products have.

Might there be a faster timeline for barley protein concentrate (BPC), sourced from an abundant and currently underutilized crop? Montana Microbial Products (MMP), which for now operates a pilot plant in Melrose, Montana, USA, is on the verge of commencing commercial-scale production of what is proving to be is a versatile product for farmed fish. In extensive feed trials over the past few years, BPC was shown to be a fully digestible, high-protein feed ingredient for multiple species of fish, even at high inclusion levels.

Instead of building a new barley processing plant, company co-founder Clifford Bradley told the Advocate that the company is poised to soon announce technology-licensing partnerships with existing manufacturers, one in North America and another in Europe.

Bradley is bullish on barley as a raw material because it has virtually no downside. And he has the competition clearly identified.

“Barley fits all the sustainability criteria,” he said. “It grows in places where it doesn’t compete with other food crops, in cold and warm climates. In Montana, the field crops are wheat and barley. We’re not burning the Amazon to make more soybeans.”

Barley supplies are robust, at 156 million metric tons (MT) annually, according to the U.S. Department of Agriculture. Montana and the rest of the United States produce about 3 to 4 million MT of barley a year, but neighboring Canada produces more than 10 million MT and the European Union more than 60 million MT. “We’re not likely to run out of barley,” Bradley stated.

And wherever barley is grown it needs little irrigation and very little in the way of fertilizers and pesticides, so inputs are quite low in comparison to other field crops. Bradley also notes that barley is not genetically modified and is “unlikely to be so anytime soon.”

Best of all, BPC would eventually end up on the low end of the feed-ingredient price spectrum. Regular feed-grade barley is about $160 per ton, said Bradley, and the high-protein strain of barley that’s perfect for making BPC is not in favor with the other major barley buyer out there: Brewers say it makes beer cloudy so they prefer the low-protein, malting grade strain. “But it’s perfect for us,” said Bradley of the high-protein variety, which he hopes to procure on a contract basis with growers in Montana.

It takes five tons of barley to make one ton of BPC, which Bradley envisions will sell for about $1,000 to $1,100 per ton. That’s competitive with soy protein concentrate, which aquafeed manufacturers have used successfully for decades. Fishmeal costs roughly $1,500 per ton.

For these reasons, feed manufacturers might soon go bonkers for barley.

“New ingredient suppliers often come in [saying they want to be priced at] 96 percent of fishmeal. These guys want a price they can make money on and that feed manufacturer can make money on,” explained renowned fish nutritionist Rick Barrows, who has been working with MMP ever since it turned its attention to aquaculture about seven or eight years ago. “As a feed formulator, it’s exciting to have another tool in the toolbox. I think they could sell it all day long.”

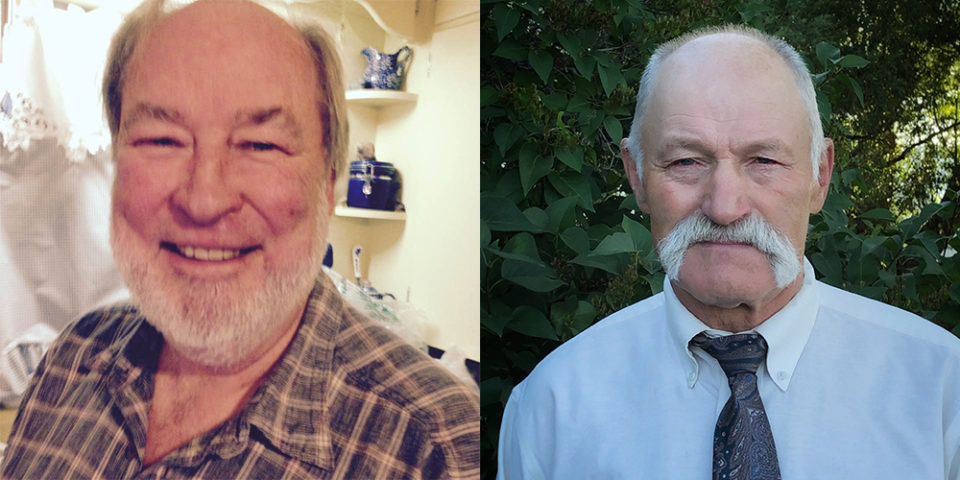

Montana Microbial Products co-founders Cliff Bradley (left) and Bob Kearns.

Enzymatic fractionation

Barrows, who left the U.S. Department of Agriculture’s Agriculture Research Service in 2016 to start his own company, Aquatic Feed Technologies have tried numerous ingredients in aquafeeds over the years and has successfully developed diets for a range of fish species, trout, and salmon in particular. Salmonid species, he said, are sensitive to some soy products, which have a variety of compounds that can have a negative effect on growth and physiology. Soy products have also been shown to cause diarrhea in salmonids, and while that’s not a major health concern for the fish, he added, it can be a messy problem for operations that use land-based tanks and recirculating aquaculture systems (RAS), which re-use production water multiple times.

“Barley doesn’t cause diarrhea, which makes it suitable for RAS,” he said.

And once the barley is de-hulled, Barrows said it is fairly easy to work with, although he struggled with it personally in the past.

“I was once trying to make a barley protein concentrate and ended up shooting barley all over the wall of my lab,” he said.

He eventually met with Bradley and his business partner Bob Kearns over a barley beverage (beer) and was convinced that, with their microbiology (Bradley) and engineering (Kearns) backgrounds, they would stand a better chance as a team at coming up with a new solution for aquaculture.

They later applied for a patent and got it, with Barrows as the lead investor, and started seeking out commercial partners for feeding trials. Clear Springs Foods, a rainbow trout farmer in Idaho, was first to bite and commenced a trial with 375,000 trout on a diet with a BPC inclusion rate of 30 percent. The fish showed no difference in feed conversion ratio (FCR), growth, taste, flesh quality or color when compared to fish raised on a conventional diet. Other trials showed that fish raised on diets including BPC had improved energy retention and overall performance similar to fishmeal at inclusion rates of 22 percent. Bradley said that fish can be fed diets with up to 45 percent BPC, a “major commercial advantage” that is also good for salmonids, which have specific digestibility needs.

“Everybody thinks of protein concentrate as the driver [for salmonid feed ingredients], but one of the things that are equally important is low fiber,” Bradley said. “Trout and salmon can’t digest fiber. Our [BPC] is less than 5 percent crude fiber, which is almost as important as the 60 percent protein.”

That 60 percent mark is achieved through a proprietary process that Bradley dubbed “enzymatic fractionation.” Once the barley is hammered into flour it is mixed with water and treated with various enzymes, temperatures and hold times. Much like ethanol is derived from corn, MMP converts the starch but also beta-glucans and most of the fiber that’s left in the barley. The protein comes through the process in an insoluble stage and is recovered via centrifuge before being dried into powder form.

A coproduct of this now-separately patented manufacturing process has tremendous value, he added: “We make a lot of glucose. Big fermentation plants need a sugar source.”

A look inside the Montana Microbial Products pilot plant in Melrose, Montana. Photo courtesy of MMP.

Barley business plans

Bradley and Kearns have educated themselves on the aquaculture industry over the past five years and have learned about how to approach this business opportunity from credible and well-connected sources. Aside from Barrows, who told the Advocate that he considers Bradley and Kearns good friends but is not receiving any financial benefit, Montana Microbials entered the Fish 2.0 Global Innovators Forum, where Bradley presented and won the “U.S. seafood” track, learning a lot about the business along the way.

“It’s been a pleasure to work with MMP over the past year,” said Monica Jain, Fish 2.0 executive director. “By using barley as the core ingredient in fish feed, MMP offers a path to meet the demands of the growing aquaculture marketplace – both in terms of volume and price. It’s exciting for us to see solutions needed for the sustainable seafood sector coming out of places like Montana, demonstrating how growing the sustainable seafood the marketplace can improve economies in landlocked as well as coastal communities.”

MMP is also part of the most recent cohort of Hatch, the international aquaculture business accelerator. Bradley said he learned a lot about shrimp production and where he got connected with a manufacturer that may soon license MMP’s technology. He also said he was learned that shrimp feed is produced with high inclusion rates of fishmeal, up to 30 percent, which he said was an eye-opener.

Carsten Krome, CEO of Hatch, which mentors companies through an intensive, eight-week program and provides seed funding in exchange for an equity stake said MMP is one of its “best performing” companies.

“Their product has massive potential and it has been tested in commercial trials with great results over the whole lifetime of the fish,” he said. “The low input costs of barley being the cheapest crop out of all, also helps.”

Krome pointed to the South American soy industry as one that needs to be “challenged with more sustainable alternatives.”

“The barley protein is a perfect solution,” said Krome, who typically works with startups and technology-focused companies. Montana Microbial Products was founded in 2002, and Bradley and Kearns have worked together for about a quarter-century.

“Bob and Cliff are very good and experienced entrepreneurs, which, as always, is just as, if not more, important as the technology itself,” said Krome.

For MMP, getting to this point has taken time because of the capital requirements for building an industrial plant have been prohibitive, hence the technology-licensing deals.

“If you need to raise $2 million, that’s gotten a lot easier” with mechanisms like online crowdsourcing platforms, Bradley said. “For the most part, the capital requirements [of other Hatch participants] are a lot less than ours. If you’re going to build a 20,000-ton barley plant, you need $40 million. It’s an industrial plant, no way around it. That’s been difficult for us.”

Source: Global Aquaculture Alliance