Energy Use in Aquaculture Pond Aeration Part 2/2

| Wed, 08 Jan 2020 - 13:45

Electric motors

Synchronous induction, alternating current motors of different types and sizes are used to power aerators. Smaller electric motors (1 to 3 hp) often are single-phase and operate on 110-120 volts (V) or 208-230 V, while larger motors usually are three-phase and operate on 208-230 V or even 460 V. Motors usually are rated at full load to require a specific current measured in amperes (Table 3); the amperes required double between 115 V and 230 V motors and between 230 V or 460 V motors.

Boyd, aeration Pt. 1, Table 3

|

Motor power rating (hp) |

Single phase (115 V) |

Single phase (230 V) |

Three phase (230 V) |

Three phase (460 V) |

|

1 |

16 |

8 |

3.6 |

1.8 |

|

2 |

24 |

12 |

6.8 |

3.4 |

Table 3. Full-load amperes for single-phase and small,

three-phase electric motors

Source: http://mechreps.com/PDF/MRI_Formulas_Conversions.pdf

The efficiency of electric motors is calculated as the energy output by the motor shaft (brake power) divided by the energy input to the motor (wire power) as follows:

kW = Brake hp × 0.746 ÷ Motor efficiency

The typical efficiencies of small electric motors are provided in Table 4. Motors should be operated at around 75 percent full load at which service life and efficiency are greater than at full load. A 10-hp, 230 V, three-phase motor operated at a brake power of 7.5 hp would use around 6.32 kW or 6.32 kW·hr of electricity per hour.

Boyd, aeration Pt. 1, Table 4

|

Electric motors |

Efficiency 1 (%) |

Small (<25 hp) stationary internal combustion engine |

Efficiency (%) |

|

1-4 hp |

78.8 |

Ethanol (E100) |

20-25 |

|

5-9 hp |

84.0 |

Liquid propane gas (LPG) |

25-30 |

|

10-19 hp |

85.5 |

Gasoline |

20-30 |

|

20-49 hp |

88.5 |

Diesel |

28-32 |

Table 4. Efficiencies of small, electric motors and small,

stationary internal combustion engines.

Source: https://www.engineering toolbox.com/electrical-motor-efficiency-d_655.html

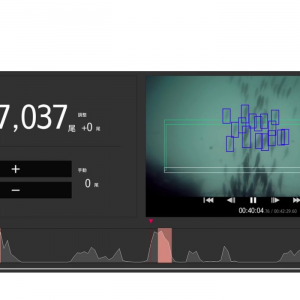

The amperes of electricity used by a motor is roughly in direct proportion to load between 50 and 100 percent full load (Fig. 1). The amperes drawn by an aerator motor can be easily measured with an ammeter during motor operation and the approximate load estimated. There is a substantial no-load current by electric motors, and they waste electricity when substantially under-loaded. The amount of power required to operate paddlewheel aerators increases with greater paddlewheel depth at any rotation speed. Attention to the depth of paddle tip submergence is important because it can change as the floats for aerators shift during operation. This results in greater or lesser submergence of paddles which can lead to overloading or under-loading of motors.

Fig. 1: Load versus fuel use by internal combustion engines and current use by electric motors (prepared with information from http://dieselserviceandsupply.com/Diesel_Fuel_Consumption.aspx and from http://energy.gov/sites/prod/files/2014/04/f15/10097517.pdf).

The rotation speed of electric motors varies with the number of magnetic poles in the motor (Table 5). Motor slip under-load reduces output shaft speed by 3 to 5 percent in 1 to 5 hp motors and by around 2 to 3 percent in motors of 7.5 to 20 hp. Motors for paddlewheel aerators usually have a shaft speed of about 1,735 ppm. By contrast, paddlewheels, depending upon their diameter, transfer oxygen most efficiently at 80 to 120 rpm. Motors that turn at such low speeds are more expensive, and speed reducers are placed in the drive train of aerators to allow higher speed motors to be used.

Boyd, aeration Pt. 1, Table 5

|

Magnetic poles |

Electrical frequency, 50 Hz |

Electrical frequency, 60 Hz |

|

2 |

3,000 |

3,600 |

|

4 |

1,500 |

1,800 |

Table 5. Electric motor rotation speed as related to a number

of magnetic poles of motor and electrical frequency.

Source: https://www.engineeringtoolbox.com/synchronous-motor-frequency-speed-d_649.html

There also is considerable use of propeller-aspirator-pump aerators in shrimp ponds. Most of these aerators have two-pole motors that rotate at about 3,600 rpm (Table 5). This type of aerator does not transfer as much oxygen per unit of energy if it is supplied with a four-pole motor. Vertical pump aerators for aquaculture typically are supplied with a four-pole motor.

When electric motors are started up, an inrush of electric current is necessary to start the rotor and accelerate the shaft to full speed. For single-phase motors of 1 to 10 hp, the inrush current is about three times the full load motor current requirement in amperes. For three-phase motors, the inrush current is about twice the full load current. Large motors usually are started with a motor controller (often called a motor starter) with fuses that withstand the large ampere input at startup.

Next Part of The Article: https://www.minapoli.com/info/energy-use-in-aquaculture-pond-aeration

Source: Global Aquaculture Alliance